The European Spallation Source (ESS) is a multi-disciplinary science and research facility under construction, near Lund, Sweden.

The ESS vision is to build and operate the world’s most powerful neutron source, enabling scientific breakthroughs in research related to materials, energy, health and environment.

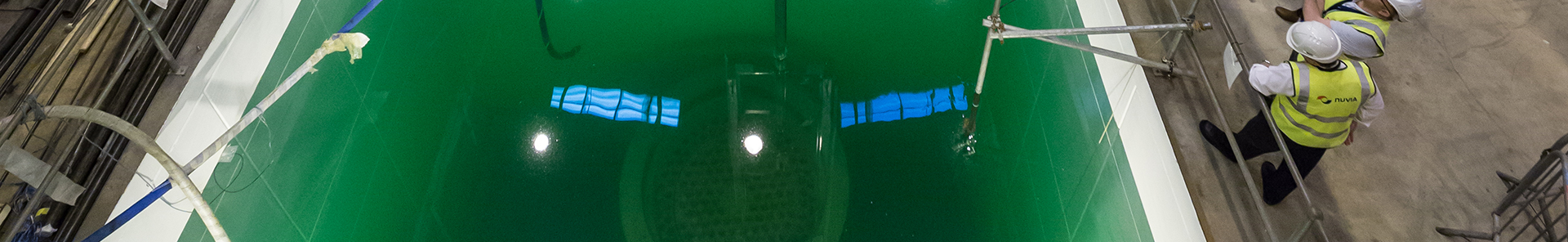

Central to the facility is the Target Station where high-energy proton pulses are directed to a Target Monolith where spallation occurs, generating a vast number of neutrons Items within the monolith become radioactive through high energy particle activation.