The Legacy NUVIA has decades of specialist experience undertaking decontamination for the nuclear, oil and gas, defence and private sectors. Through our historic evolution from the United Kingdom Atomic Energy Authority (UKAEA), through AEA Technology and NUKEM, staff have developed methodologies that provide safe, effective and efficient solutions to our clients.

Decommissioning and Site Services Decontamination

OUR CAPABILITIES

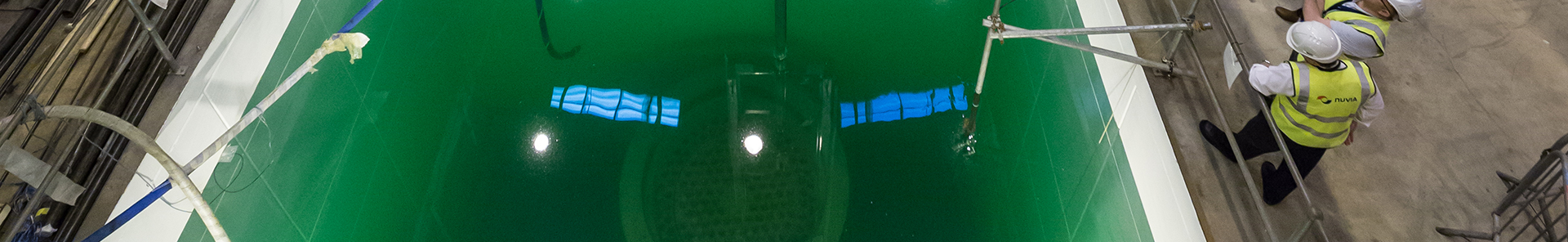

Supporting the operations and decommissioning within UK nuclear establishments, numerous tasks have been successfully completed to remove loose and fixed contamination both from surfaces and embedded within structures to minimise the volume of in-scope waste that requires specialist handling, processing and transfer to limited approved waste disposal sites.

These decontamination works can make significant cost savings in waste disposal. Methods utilised within this field include:

- Diamond wire sawing to size reduce concrete and metal structures, either for removing the contamination or for packing into appropriate transport containers.

- Abrasive mechanical scabbling, for removal of surface contamination. These can be either hand or machine operated.

- Removal of ground contamination by excavator. Bucket monitoring allows immediate sentencing of waste to be undertaken and reducing volumes for in-scope disposal.

- High pressure water washing incorporating suction and filtration to capture solids from tanks.

- Use of hand tooling to remove contamination on small or intricate equipment.

Supporting the UK Oil and Gas industry, NUVIA operates a dedicated decontamination facility which effectively removes NORM (naturally occurring radioactive material) from both downhole and surface operated equipment and pipework allowing the client to either reuse or recycle the equipment.

Methods utilised within the facility include:

- Ultra-high pressure water jetting (up to 2,500 Bar) in both external configuration (utilising a hand-held lance) and internal configuration (using a remote lance).

- Abrasive scabbling (removal of contamination inside tubing).

- Large dry shot blast booth for the aggressive removal of surface contamination.

- Wet shot blast glove box for the removal of contamination from, small, intricate equipment.

- Diamond wire sawing for size reduction of components for either decontamination or direct disposal as waste.

- Hydraulic torque machine for the breakdown of equipment for decontamination.

NUVIA’s decontamination facility operates within the scope of an EPR Permit issued by the Environment Agency. Ventilated containments, monitoring systems and robust operating instructions ensures compliance with the environmental Permit and statutory safety requirements.

Similar capabilities from the reactor and oil and gas sectors have also been utilised for the defence, chemical and private sectors.

OUR PEOPLE

NUVIA invests in their staff to ensure appropriate competence is developed by training and experience. This ensures that a team of highly qualified, professional and experienced employees with an extensive range of qualifications and experience is available to support every project. Additionally, we share our knowledge and work collaboratively within our organisation and with our clients to ensure that they are benefitting from our years of experience.

- Specifically for decontamination, the following examples of staff are utilised:

- Decontamination Operatives and working Supervisors. All either hold, or are working to, an NVQ in Decommissioning. Specialist training in, for example, water jetting, diamond wire sawing, pressurised suit operations, tooling, basic radiation protection is also held by many operators.

- Site Manager(s). Hold either Site Manager Plus (SMSTS) or IOSH Managing Safety. The majority also hold additional training in areas such as First Aid and waste disposal.

- Radioactive Waste Advisors (RWA) to give advice on matters relating to the disposal of in-scope waste.

- Radiation Protection Advisers (RPA) to give advice on matters relating to radiological protection, e.g. Radiological Risk Assessments, dose restraints and shielding

- Radiation Protection Supervisor(s) (RPS) to give advice and implement local arrangements for radiological protection.

- Across the company, NUVIA has many specialists who can be utilised for specific duties or to give advice as and when required.